Frame Member Data - Canopy

Beam with Inset Girt

(Revised: 06/04/08)

1)

Adjust

Canopy Beam Length

|

View A

View B |

If possible,

designer should design the canopy beam bolting plate to have a flush

condition at the FO (flange outside).

Before changing the connection get approval

from the designer! 1)

Confirm

any changes design will require for the top of canopy beam bolting plate to

be flush with the FO. Possible changes may include: ·

Bolting

plate material change ·

Different

weld sizes or type ·

Change

to bolt size or quantity 2)

Adjust

canopy beam length using Geometry Tool so bolting plates meet correctly. ·

The

bolting plates overlap into each other in View A ·

View B shows plates properly

aligned |

2)

Change

Canopy Beam Cut in Plate to a Flush Condition at the FO

|

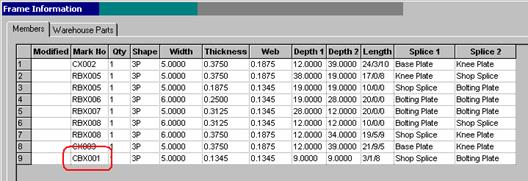

1)

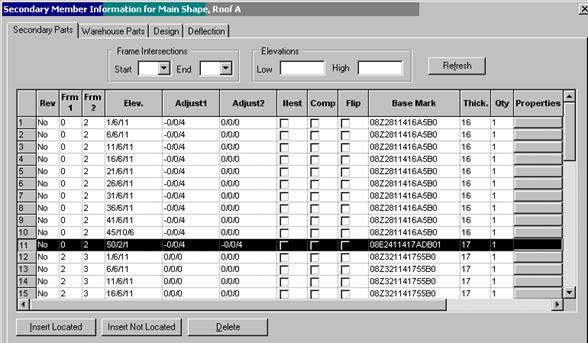

Go

to Frames/Member Data/file name/Wall

x/frame location - double click to open Frame Information 2)

Select

the canopy beam CBXxxx then pick the Properties button

|

|

|

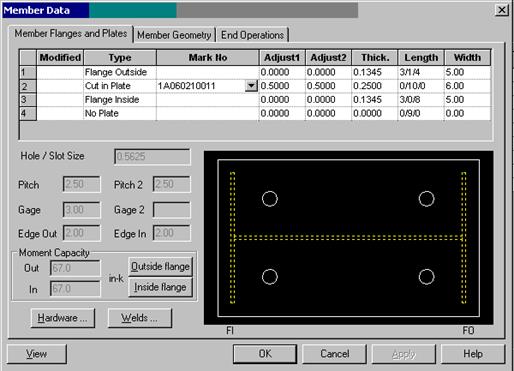

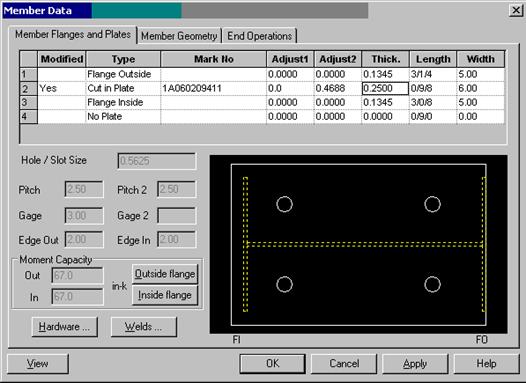

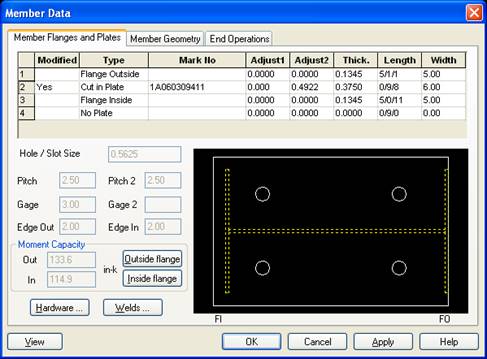

3)

The

element to be modified is the Cut in Plate 4)

The

plate in the example has a ½” cantilever past the FO and the FI.

|

|

|

5)

To

bring the Cut in Plate flush with the FO, change the Adjust 1 dimension to 0.000. 6)

The

part length will also need to change by the same amount. In this example the

plate was 10” (0/10/0). It needs to be changed to 9 ½”

(0/9/8). Once data has been entered hit the Apply button, the plate becomes

flush with the FO. a.

If

the Cut in Plate length is not changed the plate will cantilever further past

the FI. b.

go

into the welds and change the weld at the FO from Fillet to CJP Full Pen and

add a note for the shop to “grind smooth”. 7)

Hit

Okay or Apply until you are back to the model view to accept and save the

changes.

|

|

|

|

8)

Connection

should now look similar to example at left. 9)

Notice

holes do not align, now the canopy beam Cut in Plate holes need to be

modified. 10)

Go

to - Frames/Member Data/file name/Wall

x/frame location 11)

Select

the canopy beam and hit the Properties… button. 12)

Select

the Cut in Plate line. |

|

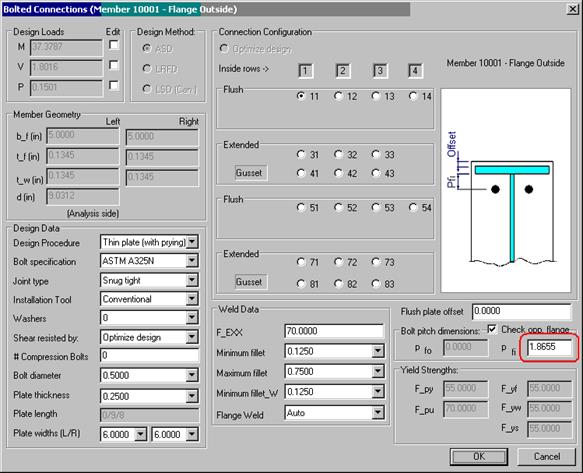

13)

Select

the Outside Flange Button. This will open the Bolted Connections screen.

14)

The

pfi dimension will need to be adjusted. a.

The

original plate had holes 2” from the edge. The hole is still being

located 2” from the edge.

(You can determine this by adding the flange thickness to the pfi

dimension.) b.

The

½” that was deducted for the cantilever past the FO must also be

removed from the pfi distance. 15)

If

the plate size (thickness or width) or bolt diameter needs to be changed it

can be done on this screen in the Design Data section. Hit Okay. 16)

If

a standard plate was being used it will be replaced by a user plate after

these changes are made. a.

This

example started with plate 1A060310011 but has been replaced with

008SP060030094.

17)

Select

Okay 2 more times to get back to

model. The holes should now be aligned.

|

|

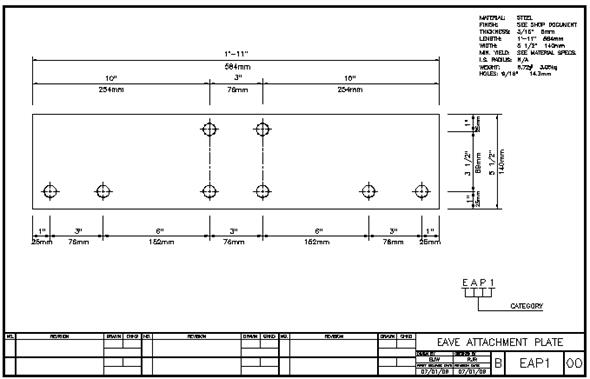

3)

Create an

Eave Strut Attachment Plate

|

1)

If

the standard plate EAP1 can be used: a.

Add

to a Vision warehouse or increase the quantity on the Final Build

Notification form b.

Add

the additional bolts to the warehouse. Do not forget the shims if a steeper

slope. c.

Add

a detail similar to one shown below to the Roof Secondary SED sheet

|

|

2)

If

additional bolts are required as would happen with a strutted connection, a user

plate will need to be created in Vision under User Clips. a.

Layout

plate configuration and input under User Clips b.

You

must use a material thickness available in User Clips. Check with design for

minimum allowable thickness. c.

Create

Exception Drawing for the plate. See below.

d.

If

there is already a strutted connection such as RS12PE at the location, no

additional bolts will need to be added. Do not forget the shims if a steeper

slope. e.

Add

a detail similar to one shown below to the Roof Secondary SED sheet

|

4)

Punch

Frame for Eave Strut Attachment Plate

|

1)

Go

to Frames/Data/shape name/wall number/ and select frame to add

punching to the FO of the rafter. 2)

A

condition that would be non-strutted similar to RS12PA can use plate EAP1.

The punching should be located as shown below.

|

|

3)

A

condition that would be strutted similar to RS12PE will need a user plate.

Locate the punching as shown below or as the connection requires.

|

5)

Add

Punching to Eave Strut if Needed

|

1)

The

eave strut may require additional holes for the offset condition created by

the eave strut attachment plate. First verify if the holes needed are already

on part in the Holes/Subunits tab under the Properties section of the eave

strut. A hole code of 1, 2 or 7 may already be at the required location and

can be used. 2)

If

hole code is not at needed location go to Secondary/Member Data/shape name/Roof Surface/ select

the eave strut and select and open the Properties button then add holes.

|